10 10 03. The Pall Rings Company.

Https Www Environmental Expert Com Products Pall Ring 55335

Crucially it also has two rows of punched out holes with fingers or webs turned into the centre of the cylinder which significantly increases the performance of the packing in terms of.

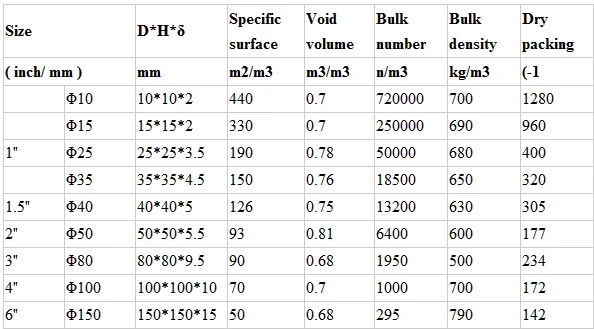

Pall ring packing factor. They are suited for low pressure drop and high capacity applications. Pall rings are the most common form of random packing. The Technical Parameter of Metal Pall Ring.

Pall rings function with versatility high resistance to fouling high temperature and can be easily soaked. Mm PALL Rings made of metal with a tower packing factor of 66 and 2 50 mm TORUS SADDLES made of ceramics with a tower packing factor of 130. Contacting packing for carbon dioxide degassing tower acid fog purifying tower ozone contact reaction tower and other reaction towers.

IMTP Saddle No. The tower packing factors show that the gas flow rate for metal PALL Rings is 40 percent higher than for the TORUS SADDLES. Metal pall ring is commonly made of stainless steel or carbon steel.

1 12 38mm 32. The Pall Ring is an advance on the Raschig Ring with similar cylindrical dimensions. The correct choice of packing is of decisive importance for optimum process efficiency in the.

The pall ring is considered worlds most common random packing type. Pall ring packing is a great improved open-cell ring-shaped packing developed on the basis of Raschig ring. And by introducing a wetting factor f which reflects the change in the packing surface area as a result of wetting.

PACKING FACTOR R Ceramic 15mm 825 290 62 540 Raschig Ring 19mm 840 260 68 255 25mm 650 190 72 160 38mm 600 135 74 95 50mm 570 92 76 65 75mm 560 79 78 36 R Carbon 12mm 679 360 60 450 Raschig Ring 18mm 590 240 66 260 25mm 600 195 65 180 37mm 590 140 65 125 50mm 530 98 68 65 P Stainless 16mm 580 340 93 70 Pall Ring Steel 25mm 435 207 94 50 38mm 355 128 95 28. Thorough tests have shown that the tower packing factors. 16 16 03.

For over fifty years random packings are effectively used to improve a towers performance. 6 6 03. IMTP Saddle No.

Technical Parameters of Metal Pall Ring Item Ring diameter mm Diameter Height Thickness mm Surface Area m2m3 Void Fraction Bulk Quantity pcsm3 Packing Factor m-1. The five most popular nominal diameters of metal pall ring widely applied to industrial manufacture are DN 16 DN 25 DN 38 DN 50 and DN 76 mm. Advantage over standard Pall rings.

Metal Pall ring packing was developed by BASF in Germany in the 1940s on the basis of the Raschig ring packing. Pall rings Ceramic 50 mm 7502 1552 0754 0233 Hiflow rings Plastic 50 mm 50 mmhvdr 7640 8150 1313. Gas dehydration Demethanizing Tall oil fractionating CO2 removal Vacuum crude stills H 2S contacting Liquidliquid contacting Free Space Packing lbsft3 kgm3 Factor F Bulk Density SS MTL.

Pall rings have similar cylindrical dimensions but has rows of windows which increase performance by increasing the surface area. Item Size mm Bulk Density 304 kgm 3 Number nm 3 Surface Area m 2 m 3 Voidage Dry Packing Factor m-1 MPRT-01. The metal pall ring is one of MTEs metal random packing products.

The design of the pall ring is an improvement of the raschig ring. IMTP Saddle No. IMTP Saddle No.

Although similar in outward appearance to Pall rings AIPR packing offers more. AMACS improved pall ring packing can improve per- Applications. Packing type Packing type Size Size Packing factor Flft Packing Density kgm³ Surface m²m³ Void Fraction Raschig ring.

Metal pall ring random tower packing Tall-Pak Hy-Pak is made of a metal thin sheet and have a special structure there are two row window with ligules towards inside on the ring wall each row window has five ligules bend to inside of the ring and point to. Compared with plastic pall ring metal pall ring packing has higher mechanical strength and better mass transfer performance. IMTP Saddle No.

1 12 38mm 83. The AIPR provides superior distribution and avoids channeling towards the vessel walls. This AMACS improved Pall ring design allows greater capacity lower pressure drop and even and thorough gas and liquid bed distribution.

AMACS Improved Pall Ring Random Packing AMACS AIPR tower packing is basically a more finely tuned and better performing Pall ring. Generally the opening area accounts for about 30 of the total area of the ring wall so that the gas and liquid in the packed tower can pass freely through the window hole improving the gas-liquid distribution and making full use of the inside of the ring. Pall rings packing shows its interior and exterior surface contact which is beneficial to resist plugging nesting and fouling all along in with the distribution of liquid and gas.

13 13 03.

Ceramic Pall Ring Ceramic Random Packing For Scrubbing Tower Ceramic Random Packing Factory

The Ultimate Guide On How To Choose Random Packing

Plastic Pall Ring Plastic Random Packing Ceramic Plastic Metal Random Packing Ceramic Ball Catalyst Support For Tower Packing In Power Petroleum Chemical Metallurgy Pharmaceutical Environmental Protection Aerospace And Other Industries

Hetp Pall Rings Pressure Drop Buffalo Brewing Blog

Selection Criteria Of Packings Separation Technologies

Random Packing A Plastic Pall Rings B Metal Pall Rings Metal Download Scientific Diagram

Low Price 3mm 6mm 10mm 15mm 20mm 25mm 50mm 76mm 100mm Ceramic Raschig Ring Packing Buy Ceramic Raschig Ring Ceramic Rings Raschig Packing Ring Product On Alibaba Com

Plastic Hollow Sphere Ball Packing Raschig Rings Packing Factor Buy Padding Plastic Pall Ring Plastic Hollow Sphere Ball Raschig Rings Packing Factor Product On Alibaba Com

Properties Of Structured And Random Packing Download Table

China Stainless Steel Carbon Steel And Alloy Pall Ring Random Packing China Pall Ring Random Packing

Pall Rings Ceramic Pall Ring Gujarat India

Metal Pall Ringpingxiang Ksource Chemical Packing Co Ltd

Metal Pall Rings Pall Ring Company Australia

Plastic Pall Rings Pall Ring Company Australia

Heat Resistant Plastic Pall Ring For Chemical Plant

0 comments