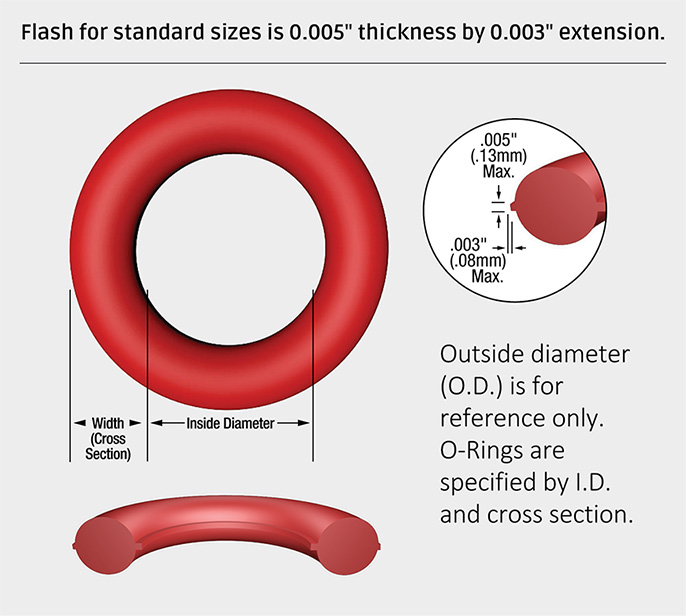

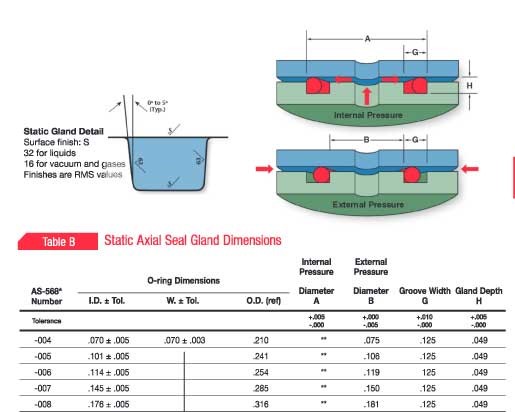

Table B Static Axial Seal Gland Dimensions Copyrights 1999 Apple Rubber Products Inc. The o-ring in this configuration fills approximately 90 of the groove.

O Rings Standard As568 Iso 3601 Apple Rubber Products

Apple Rubber has provided some helpful resources to design O-ring geometry as well as choose the right material for the medium and temperature range the O-ring will operate in.

Apple rubber o ring groove design. Male or Plug - the O-ring groove is located on a plug which is inserted into the housing or cylinder fig. No less than 75 of the seal cross-section should be contained within the groove to ensure the seal does not roll or extrude out of the groove. The groove shape is very similar to that of face seals.

Click here for more information on face seal groove design. As a global innovator for industries ranging from aerospace to medical and everything in between were solving the worlds toughest sealing challenges one o. Depending on your application you can have the groove be cut in either the piston or the bore.

Find O-rings by size temperature range material type compliance and more. Standard and Non-Standard Sizes. There are two types of radial designs.

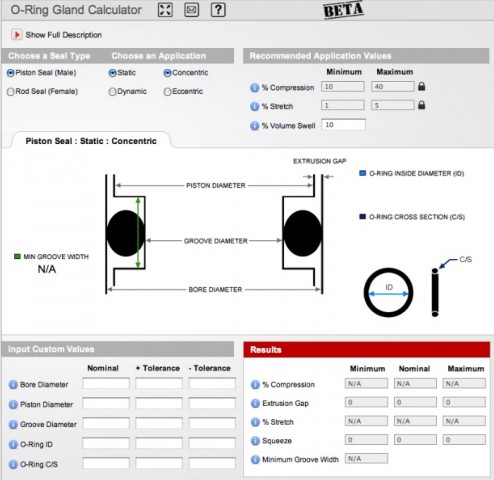

Rubber Seals Sealing Devices O-Ring Seal Design Apple. The biggest thing I used it for was their O-ring Calculator which helps size O-Ring glands for proper size and compression of the O-Ring. Female or Tube - the O-ring groove is located in the housing or cylinder and a tube is installed through the O-ring lD.

One of the faces will be completely smooth and one will have an o-ring groove cut into it. Customers tell us that our seal design guide is very informative The tour then proceeds through the material selection guide discussions of seal types and standard O-Ring size charts. Over the last 50 years Apple Rubber has pushed the boundaries of rubber seal design.

Apple Rubber offers a direct approach to purchasing o-rings from one of the largest inventories in the sealing industry. Note the Quad-Ring Brand. You can find that link here.

The design of the groove where the o-ring sits plays a major role in how the o-ring performs its sealing role. The gland is basically a groove dimensioned to a certain height H and width W Figure 1 to allow a fixed compression of the o-ring. The wrong size groove makes the best o-ring.

Pushing the Boundaries of Seal Design for 50 Years. If we dont have it we can make it. Male or Plug Seal design.

The best o-rings are useless without the right groove design which becomes increasingly important the more demanding the application environment. But it also includes chemical compatibility charts and material descriptions. 10 O-RING SEALS THEORY AND DESIGN PRACTICES Theory.

Standard and Metric Sizes. Try our new Online O-ring Store. For gases and 32 Ra max.

Designing the parts of an application where o-rings will be applied is broadly termed o-ring groove design. Experimental data shows that as the o-ring fills more of the groove and begins to touch the groove on all 4 sides the force needed to actuate the seal increases. In-house tooling and manufacturing allow us to expedite tooling and delivery.

Benefits of our inventory. Find the right o-ring groove design and easily order your o-ring online from the worldâs largest inventory network. In our updated edition we get a little philosophical.

Expert Application Engineering Assistance. How does an O-Ring work. Our o-ring groove design guides list default o-ring groove dimensions for the most basic applications and are intended to be used with the following o-ring groove design considerations to engineer an o-ring gland to optimize specific application performance.

O-ring groove design guides offer default dimensional guidance on the most basic o-ring groove design applications. Review the general o-ring groove design. We reflect on the dynamic growth of Apple Rubber.

In order to seal properly the o-ring has to deform in the application by being compressed and stretched in any number of ways. Groove Width G Gland Depth H Tolerance 005-000 000-005 010-000 006-000 Internal Pressure External Pressure O-Ring seal sizes not listed are not recommended for axial seals because the seal ID after installation becomes too small for practical use. When the o-ring volume approaches the groove volume the o-ring begins to shear when inserted as shown in Figure 4.

An o-ring seal consists of an o-ring and a properly designed gland which applies a predictable deformation to the o-ring. AS568 and ISO 3601 standard sizes. O-ring groove design considerations and engineering guides for static face seals metric o-rings static dovetail o-rings static rod-piston o-rings and dynamic rod-piston o-rings.

The recommended compression is 10-40 static 10-30 dynamic and the stretch is 1-5 when stretch is required. Find and Buy Marco O-rings Online. The O-ring calculator will show you the compression stretch squeeze extrusion gap and minimum groove width with a 10 swell assumed.

One general guideline for good O-ring application and design is to maintain a range of sqeeze on the O-ring 10-40 for static and no more than 30 for dynamic. If you are designing a face seal select the Quad-Ring Brand with an inside diameter which will position the Quad-Ring Brand on the side of the groove opposite the pressure.

The Apple Rubber Seal Design Guide Turns 25 Official Apple Rubber Blog

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

Insten Wristlet Flip Leather Fabric Cover Case Lanyard W Stand Card Holder For Apple Iphone 11 Pro Max Pink In 2021 Leather Leather Fabric Phone Accessories Shop

Groove Apple Watch Band Tagged 30 40 Groove Life Apple Watch Bands Fashion Watch Bands Apple Watch Bands

Nimblegrip Ergonomic Grip For Apple Pencil Apple Pencil Apple Pencil Cover Hexagon Design

New Gland Calculator Tool At Applerubber Com Official Apple Rubber Blog

Apple Rubber Introduces The New O Ring Gland Calculator For Radial Gland Designs Hot Topics

Sold Groove Original Moss Green Ring Mens Accessories Jewelry Moss Green Green Rings

0 comments